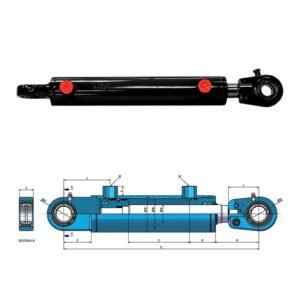

Hydraulic D/Acting Spherical End Cylinder 32Bore 20Rod 50Stroke 260Closed 1000/05

Specifications

- Bore Size: 32 mm

- Rod Diameter: 20 mm

- Stroke Length: 50 mm

- Closed Center Length: 260 mm

- Operating Pressure: Rated to 200 Bar

Features

- Swivel Pin Holes: Both at the base and rod end are 20 mm in diameter

- Ports: 1/4″ BSP (British Standard Pipe)

- Type: Double Acting Hydraulic Ram/Cylinder

Product Description

Characteristics

- Maximum Working Pressure: 200 bar

- Maximum Testing Pressure: 300 bar

- Maximum Working Speed: 0.5 m/s

- Working Temperature: -30 ºC to +90 ºC

- Oil: Mineral hydraulic oil

Material

- Rod: Chrome plated steel F-1140

- Minimum chrome layer thickness: 20 micron

- Roughness: Ra < 0.2

- Minimum surface hardness: 900 HV

- Corrosion resistance: Minimum 200 hours in neutral saline fog (ISO 9227, rating 9)

- Tube: Steel ST-52-3, DIN 2393

- Inside diameter tolerance: ISO H9

- Roughness: Ra < 0.8 micron

- Guide-Bushing: Steel F-1140, nitrited

- Piston: Steel F-1140

Seals

- Guide-Bushing:

- Dynamic: Compact polyurethane rod-seal, double lip. NBR metal wiper seal

- Static: NBR 90 shore O-ring

- Piston:

- Dynamic: Compact double-acting polyurethane seal, plus nitrile O-ring as activator. Special polyacetal guides reinforced with glass fibre

- Static: Polyamide locking sealing guide

Finishing

- Painting: Black prime painting

Recommendations

- Relief Valve: Protect the cylinder circuit with a relief valve set at 200 bar

- Oil Cleanliness: Check oil cleanliness and prevent contamination by using a filter on the cylinder circuit

- Bleeding: Bleed the circuit by slightly loosening the cylinder fittings before starting

- Welding: Do not weld on the cylinder tube. If welding on the rod or bottom is necessary, dismount the cylinder first

- Storage: Avoid outdoor storage for long periods. If unavoidable, retract the rod completely or grease it

- Cleaning: Protect the rod and oil ports during high-pressure cleaning or blasting

- Single Acting Use: If used as a single-acting cylinder, connect the unused oil port to the tank

- Dismounting: The piston is screwed onto the rod end and fixed with industrial glue. Use industrial glue when remounting the cylinder

Submit Your Sourcing Request

Related products

Showing the single result

Do You Need Any Help?