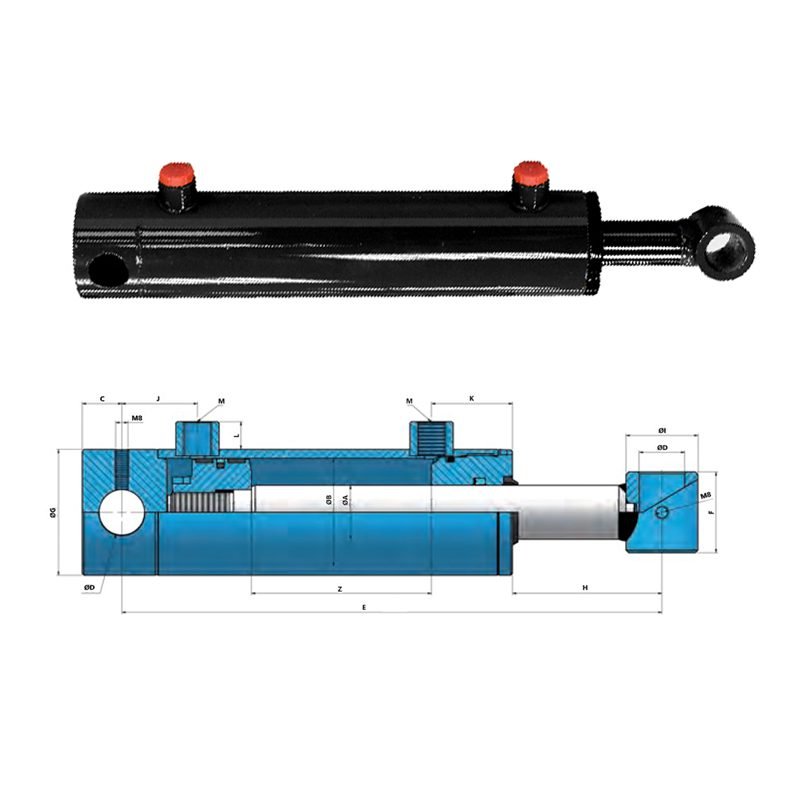

Hydraulic D/Acting Cylinder/Ram 60Bore 30Rod 100Stroke 300Closed 703/1

Product Features:

- Bore: 60mm

- Rod: 30mm

- Stroke: 100mm

- Closed Centre Length: 300mm

- Pin Hole Diameter (Base and Rod End): 25.25mm

- Ports: 3/8″ BSP

- Type: Double Acting Hydraulic Cylinder/Ram

- Maximum Working Pressure: 200 Bar

Product Description

Product Description: Double Acting Fixed Pin Holes Hydraulic Cylinders

Our Double Acting Fixed Pin Holes Hydraulic Cylinders are designed for robust performance under demanding conditions. Engineered with a maximum working pressure of 200 bar and a testing pressure of 300 bar, these cylinders offer reliable operation with a working speed of up to 0.5 m/s and a temperature range of -30 ºC to +90 ºC.

Material Specifications:

- Rod: Crafted from chrome plated steel F-1140, with a minimum chrome layer thickness of 20 microns, ensuring a roughness Ra < 0.2 and a surface hardness of 900 HV. The rod is corrosion-resistant, withstanding 200 hours in neutral saline fog as per ISO9227 rating 9.

- Tube: Manufactured from steel ST-52-3, DIN 2393, with an inside diameter tolerance of ISO H9 and a roughness Ra < 0.8 microns.

- Guide-Bushing and Piston: Made from steel F-1140, with nitride hardening for the guide-bushing.

Seals:

- Guide-Bushing: Features a dynamic compact polyurethane rod-seal with double lips and an NBR metal wiper seal, along with a static NBR 90 shore O-ring.

- Piston: Equipped with a dynamic double-acting polyurethane seal and a nitrile O-ring as an activator, reinforced by polyacetal guides with glass fiber. A static polyamide locking sealing guide is also included.

Finishing:

- The cylinders are finished with a black prime painting, ensuring durability and resistance to environmental factors.

Recommendations for Use:

- Protect the cylinder circuit with a relief valve set at 200 bar.

- Ensure oil cleanliness by using a filter in the cylinder circuit.

- Bleed the circuit before startup, avoid welding on the cylinder tube, and protect the cylinder during high-pressure cleaning.

- For long-term storage, keep the rod retracted or greased, and if dismounting the cylinder, use industrial glue when reassembling.

Submit Your Sourcing Request

Related products

Do You Need Any Help?