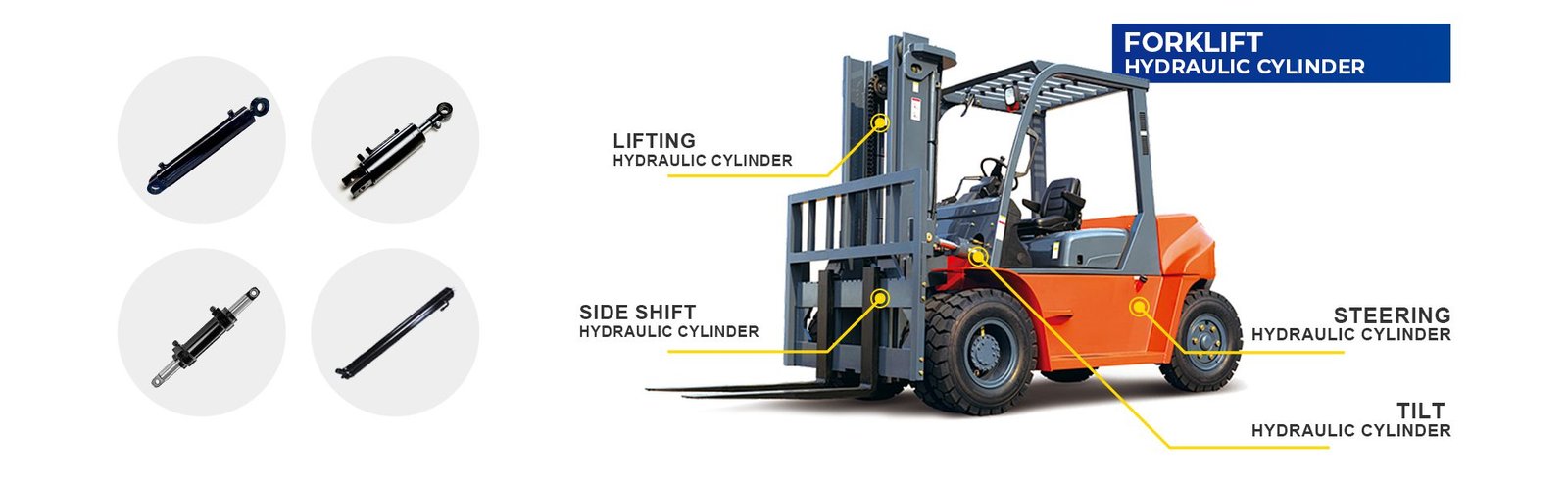

Hydraulic cylinders are essential components in the operation of forklift trucks. Hydraulic cylinders can provide the power to complete the lifting and steering operations of forklift trucks. Whether it is an electric hydraulic lift cylinder or a forklift hydraulic lift cylinder, it plays an indispensable role.

Forklift hydraulic cylinder components

Hydraulic oil cylinders usually consist of the following parts:

Barrel

The cylinder is one of the main components of a hydraulic cylinder. Its function is to provide a closed space for hydraulic oil to withstand pressure. The quality and roughness of the barrel directly affect the performance and life of the hydraulic cylinder. High quality barrels are machined with precise internal holes to ensure smooth flow of hydraulic oil in the barrel.

Piston Rod

The piston rod transmits power in the hydraulic cylinder. The pressure of hydraulic oil is used to promote the telescopic movement of the piston rod to achieve the transformation of mechanical properties and finally complete the lifting, pushing, pulling or rotating movements. The surface of high quality cylinder piston rods is chrome plated to meet the requirements of improving corrosion resistance and wear resistance.

Sealing

The seal of the hydraulic cylinder is very critical and is mainly used to prevent internal hydraulic oil leakage and debris ingress. Commonly used seals include O-rings, lip seals and retaining rings. High quality seals are generally resistant to high temperatures, wear, compression and deformation.

Tail end cover

The tail end cover is used to secure and support the hydraulic cylinder and connect other components. It is designed to withstand working pressures and external loads, so high-strength alloy materials and precision machining are used.

What is the role of hydraulic cylinders in forklift trucks?

Hydraulic cylinder is used to transmit power and operating action, mainly used for:

Lifting goods and loads

Raising the height of the goods through the telescopic action of the hydraulic cylinder.

Switching between tipping and operation

Used to achieve front and rear tipping of the truck and reciprocal switching of other operating modes.

Provides braking power and stability

Assists the truck in achieving smooth operation in complex terrain and provides braking force to improve the safety of operation.

How does the hydraulic ram work in a forklift truck?

The hydraulic cylinder uses fluid pressure to convert power. When hydraulic oil enters the cylinder, it pushes the piston rod to move, providing power and completing the action. In the electric hydraulic lift cylinder and the 12-volt hydraulic lift cylinder, energy efficiency and operating accuracy are further optimised by combining hydraulic control technology with the electric drive system. At the same time, these improvements greatly improve the durability of the equipment, allowing it to operate stably for a long time in high-intensity working conditions.

How to judge if the forklift hydraulic cylinder is faulty

The key points of forklift hydraulic cylinder failure are inspection and judgement:

Hydraulic oil leakage

If there are signs of hydraulic oil leakage, the seals, pipes and joints should be checked immediately.

Reduced performance

If the hydraulic cylinder cannot provide sufficient lifting force, this may be caused by wear on the piston rod or internal components of the hydraulic system.

Abnormal noise

If there is an air flow noise or metal friction noise during operation, the pressure balance may be disturbed or the internal components may be damaged or loose.

How to prevent forklift hydraulic cylinder failure

Preventing hydraulic cylinder failure requires regular inspection and replacement, and keeping them clean:

Regular inspection

Regularly check the hydraulic oil level, seals and hydraulic lines to ensure there are no leaks or signs of ageing.

Regularly inspect the truck for signs of damage, including hydraulic oil leaks, the condition of seals and scratches on the piston rod.

Check the level and quality of the hydraulic oil. If the level is low or the hydraulic oil is deteriorating, add or replace hydraulic oil that meets the standards in time.

Check the seals or gaskets for ageing or wear and replace them in time to prevent leaks in the hydraulic system.

Keep it clean

Clean the hydraulic system regularly to prevent the ingress of dirt and foreign matter.

Keep the hydraulic system clean to ensure that no contaminants remain inside.

Replace accessories regularly

Replace key components such as seals and hydraulic oil in accordance with the use cycle to ensure stable system operation.

Add lubricating oil to the hydraulic system regularly to reduce friction and damage and to ensure normal lubrication of the hydraulic system.

Specific operation and maintenance requirements

Improve operation

Avoid improper operation, such as overloading or sudden changes of direction, and reduce the impact of the hydraulic system.

Standardise operations to minimise equipment wear.

Check system condition

Check regularly for worn or loose seals and hydraulic lines.

Focus on checking that the pressure balance of the hydraulic system is maintained in a normal state to ensure the operation of all components.

Regular lubrication

Add standard lubricating oil to the hydraulic system as required to ensure smooth lubrication of key components.

Ensure that the lubricating oil is clean to prevent the ingress of contaminants that can affect system performance.

Bleeding the hydraulic cylinder

The gas in the hydraulic system will cause unstable operation, so it must be vented by following the steps below:

Switch off the system pressure

Turn off the system pressure to ensure the system is operating in a safe condition.

Open the bleed valve

Open the bleed valve and slowly release the gas, observing the condition of the oil.

Re-pressurise the system for testing

Pressure test to ensure there is no gas left in the system and that it is running smoothly.

How to buy a forklift ram

When individuals or companies purchase forklift hydraulic cylinders, they need to consider the following four points:

Matching selection

Make sure that it can be perfectly matched to the forklift.

Background research

Choose a supplier that values quality and provides technical support, such as EASTAI Hydraulics.

Customized needs

Add design features such as electric hydraulic cylinders according to the actual needs of individuals or companies.

Inspection standards

Improve the standards of hydraulic modules and choose the right hydraulic cylinder according to actual needs.

Contact Us

If you have any needs or questions about forklift hydraulic cylinders, electric hydraulic cylinders, 12V hydraulic cylinders, and other products, please feel free to contact us. We will wholeheartedly provide you with professional product consultation, customised solutions and after-sales service.

Eastai Hydraulics (EASTAI)

Email: info@east-ai.cn

Address: Huishan District, Wuxi City, Jiangsu Province, China

Official website: https://eastaicylinder.com/