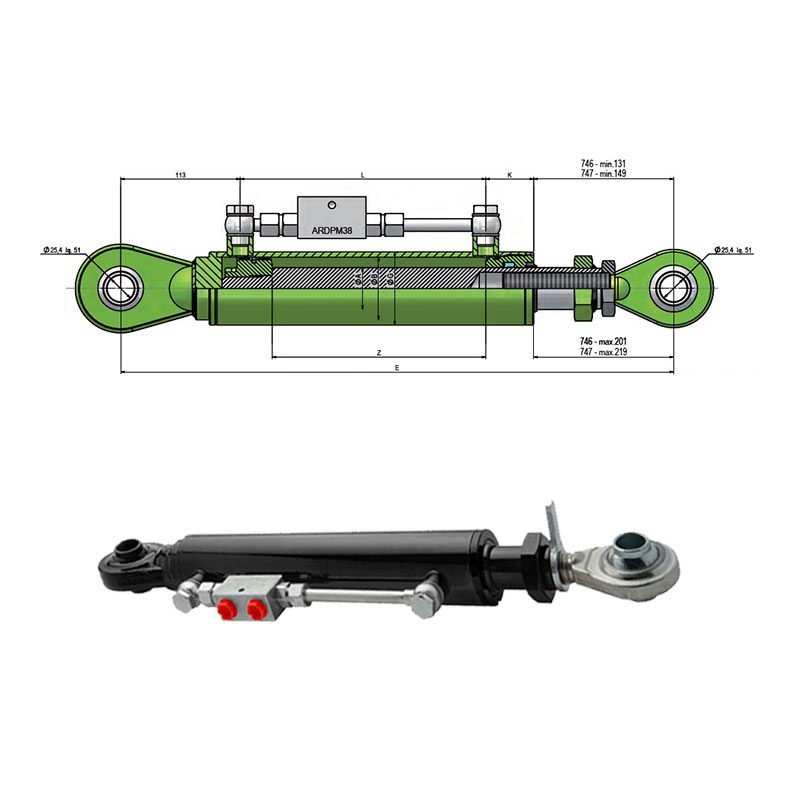

HYDRAULIC TOP LINK ADJUSTABLE CYLINDER/RAM 60BORE 40ROD 200STROKE 518CLOSED 746AAR C/W DPO CHECK VALVE

Hydraulic Cylinder Specifications:

- Bore Size: 60mm

- Rod Diameter: 40mm

- Stroke Length: 200mm

- Closed Center Length: 518mm

- Max Working Pressure: 200 Bar

- Configuration: Double acting

- Mounting Type: Pin holes at base and rod end

Product Description

Hydraulic Top Link Adjustable Cylinders

Characteristics:

- Maximum Working Pressure: 200 bar

- Maximum Testing Pressure: 300 bar

- Maximum Working Speed: 0.5 m/s

- Working Temperature Range: -30ºC to +90ºC

- Oil Type: Mineral hydraulic

Material:

- Rod: Chrome plated steel F-1140

- Minimum chrome layer thickness: 20 microns

- Surface roughness: Ra < 0.2

- Minimum surface hardness: 900 HV

- Corrosion resistance: Minimum 200 hours in neutral saline fog (ISO 9227 rating 9)

- Tube: Steel ST-52-3 (DIN 2393)

- Inside diameter tolerance: ISO H9

- Surface roughness: Ra < 0.8 micron

- Guide-Bushing: Steel F-1140, nitrided (nitride hardening)

- Piston: Steel F-1140

Seals:

- Guide-Bushing:

- Dynamic: Compact polyurethane rod-seal, double lip, NBR metal wiper seal

- Static: NBR 90 shore O-ring

- Piston:

- Dynamic: Compact double-acting polyurethane seal, nitrile O-ring as activator, special polyacetal guides reinforced with glass fiber

- Static: Polyamide locking sealing guide

Finishing:

- Paint: Black prime painting

Recommendations:

- Relief Valve: Protect the cylinder circuit with a relief valve set at 200 bar.

- Oil Cleanliness: Ensure oil is clean and free of contaminants (use a filter in the cylinder circuit).

- Bleeding the Circuit: Bleed the circuit by slightly loosening the cylinder fittings before starting up.

- Welding Precautions:

- Do not weld on the cylinder tube.

- Before welding on the rod or bottom, dismount the cylinder.

- Storage:

- Avoid outdoor storage for long periods.

- If outdoor storage is necessary, keep the rod completely retracted or greased.

- Cleaning:

- Protect the rod and oil ports during high-pressure cleaning or blasting.

- Double-Acting as Single-Acting:

- Connect the non-used oil port to the tank.

- Dismounting the Cylinder:

- Note that the piston is screwed onto the rod end and fixed with industrial glue.

- Use industrial glue when reassembling.

Submit Your Sourcing Request

Do You Need Any Help?